At Fabrication Factory, our Rapid Prototyping service is designed to accelerate the development of your projects by quickly turning concepts into tangible prototypes. This process allows for faster testing, evaluation, and iteration, ensuring that your designs are refined and optimized before full-scale production.

Using cutting-edge technologies and materials, we create accurate and functional prototypes that help identify potential issues early, reducing risks and saving time. Our rapid prototyping approach not only speeds up the design process but also enhances overall project efficiency, enabling you to bring your innovations to market faster and with greater confidence.

Our Services

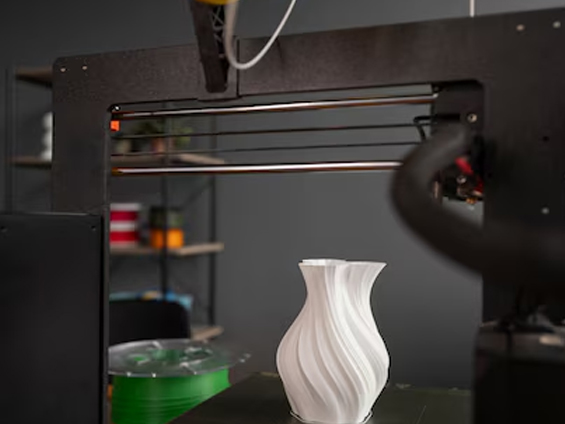

In the realm of rapid prototyping, technology plays a pivotal role in transforming concepts into practical prototypes efficiently and accurately. At Fabrication Factory, we harness the latest advancements in 3D printing, computer-aided design (CAD), and other state-of-the-art technologies to streamline the prototyping process. By integrating these tools, we are able to create highly detailed and functional prototypes that closely mirror the final product.

Our use of advanced technology not only speeds up the development cycle but also enhances precision and allows for iterative design improvements. This technological edge enables us to deliver prototypes that are both high-quality and cost-effective, ensuring that every aspect of your design is thoroughly tested and validated before full production. By leveraging technology, we provide our clients with the confidence that their products will meet the highest standards of performance and reliability, ultimately facilitating a smoother transition from concept to market.

Our rapid prototyping process includes CNC machining, which allows for precise and efficient production of complex parts and components. CNC (Computer Numerical Control) machining ensures high accuracy and consistency, making it ideal for creating detailed prototypes that meet exact specifications. This technology enables us to work with a variety of materials, including metals and plastics, to produce robust prototypes that are both functional and reliable.

We emphasize iterative development to refine and perfect your prototype through multiple stages of design and testing. This approach allows for continuous improvement based on feedback and testing results, ensuring that the final product is optimized for performance and usability. By incorporating iterative cycles, we identify and address potential issues early, leading to more successful and effective prototypes.

Our CNC plastic machining capabilities offer precision and versatility for creating prototypes using various plastic materials. This process allows for the production of detailed and complex plastic components, which are essential for testing and validating design concepts. CNC plastic machining provides a cost-effective solution for producing high-quality prototypes with excellent dimensional accuracy.

With years of experience in rapid prototyping, Fabrication Factory has built a reputation for delivering high-quality results. Our expertise in leveraging advanced technologies and industry best practices ensures that each prototype meets the highest standards of performance and reliability. Our trusted experience allows us to handle projects of all sizes and complexities, providing clients with confidence in our ability to deliver exceptional prototypes.